Navigating through the Coronavirus (COVID 19) outbreak - Updates and statements on how we are responding to keep you in business. We’re Here to Help - click for more [close]

Navigating through the Coronavirus (COVID 19) outbreak - Updates and statements on how we are responding to keep you in business. We’re Here to Help - click for more [close]

May 2024

May 28th, 2024 - the date for the dawn of a new Drupa! This Drupa of 2024 will, however, be yet another “inkjet Drupa”. How many times have we been sold the inkjet story? It’s easy to lose count.

CAUTION: The “Inkjet Streets” are STILL Not Paved with Gold

Be very careful before you put pen to paper and sign-up for the product that you believe will be the future of your print business. We do not say such things lightly – after all, it was MPL, the UK’s RMGT litho press distributor, that was one of the first to coin the phrase “Digital AND Litho”, as opposed to more often promoted solution for printers of digital OR litho.

However, what sums do you, and the print business, need to have worked out in advance of your digital print revolution? Firstly, of course, we have no idea how you are proposing to pay for this unit. Most often, for the smaller units, it will be by lease purchase. This is also part of the suppliers’ cunning way of locking you into their business, its equipment, and its supplies. As you start producing larger volumes, they will suggest that you move to the next machine in the range, thus ensuring that you continue to use their consumables. After all, that’s where they really make their money.

As for the larger, multi-hundreds-of-thousand pounds machines – well, who knows the actual price and payment terms? Interestingly, many of the large print houses installing these big beasts often go back for a second machine. Do they love it that much? Have they suddenly acquired a huge amount of additional work? Or have they found the need for a back-up press due to the rather patchy up-time of the product? Currently we have more questions than answers, and very little real data, as yet. The big players make efforts to ring-fence such detail. Our advice: tread carefully!

Why Digital?

Please note, we are certainly not knocking the digital press. They have come a long way in 20 years. High volume, low quality, transactional production has found its solution. For the rest of the industry colour and quality issues have now largely been solved, and whilst throughput, or productivity questions, are slowly and gradually being answered, that’s not a problem if you target the right work with your digital press. That means personalised print and/or very short run work, because speed is not the main issue. There is a very good article here from the Drupa web site – it details the full potential for inkjet printing equipment. Do read it. The author makes some very good points.

Our focus here though is on profitable printing. If a job doesn’t fit the above criteria regarding personalisation or small quantities, it is highly likely that it will be more profitable for you to produce the work, or at least a large portion of the work, with a modern offset litho press.

We still believe that printers, with the right balance of work, should welcome digital production to work alongside litho printing. Ok, we all know that inkjet and digital print wins hands-down when talking personalised print production – that's no surprise. How much of that work are you expecting to receive? How much personalised print does it take to pay for the digital press? Does that equal a sufficient quantity of print to equal the number of clicks that the digital supplier wants you to commit to per month?

Short-run printing – “the run of one”: that's where the money can be made with the inkjet press. Litho simply cannot compete on very short run orders. The cost of plates and of setting up the job to print will most likely make any run lower than 200 copies a good fit for digital. If that profile of work fits your business, inkjet digital could be the one!

Up-Time and Servicing

However, what happens if your digital press breaks down, or requires a very-frequent-routine service visit? Reliability is one area where litho generally trumps digital, and an ultra-reliable RMGT press even trumps other brands of litho press. If you are familiar with litho reliability then digital will blow your mind, and not in a good way! The volume of service calls, and the length of service visits, multiplied by the availability of spare parts and software / firmware updates will, we believe, be hard for a new entrant to come to terms with. As an example of service costs for the larger B2 format digital presses, we recently came across a user who was having to pay £3,500 a month, on top of a 4.7p per side click charge. That’s a chunk of change to find so regularly – and to pay before you’ve printed one saleable page.

Once you’ve done your homework and decided that a digital press fits your requirements PAUSE. Find other users of that equipment. How do they find the reliability? The service costs? The service intervals? The consistency of colour? It’s versatility regarding the printing stock that will run on the machine? The salesman you’ve been speaking to will skirt around such questions. Users are far more likely to answer your questions honestly. Try to find several users to obtain a true picture.

Cost Per A4 Page

The points we want to move towards here are, [1] what is the true cost of ownership of this unit, and [2] what is the cost of printing an A4 page with both inkjet and with litho? Our previous experience of working out these sums with printers suggests, quite firmly, that litho production wins hands down when averaging an entire workload through such calculations. Make sure here to use your own calculations regarding costs as much as possible. One printer we spoke to recently said that he had two figures for the digital A4 page cost: one provided by the equipment supplier and his own calculations. Guess which one was the more accurate!

The cost-per-page is one of the most important calculations for your business. A printing company that thrives is one that is making a profit once the work is produced and shipped to the customer. Getting a job out “on time” does not, in itself, make your business any money. Once you know your true cost for a single page, you can establish whether you are actually making any money from any job that you produce.

That all sounds very basic business sense, and you might be critical of a lot of what has been said here, but you’d been both surprised and shocked at how many printers we speak to that haven’t produced these critical numbers. They are just too focused on the “now”, on getting jobs produced on time and delivered, or beating the competition on price, rather than that most important of business basics – turning a profit.

Residual Value

Ok, so what else do you need to appreciate before you go ahead and make your purchase? Let’s throw in residual value of any equipment, as this can often help to fuel a next purchase. We’ve yet to come across a digital press that has any true value once you have used it for a few years – according to our research that’s likely to be two to four years. Your supplier might suggest that it does carry a “value”, but all they really want to do is to keep you clicking away on a newer shiny digital unit – remember that’s how they really make their money. A litho press that lasts for ten years (that’s two or more inkjet machines worth!) and is likely to still have a very reasonable resale value.

Modern litho presses, fully equipped, will produce dry prints at the delivery of the press, ready for backing-up or moving straight into the bindery. Gone are the days of piles of print waiting to dry before going through the next phase of production. Fully equipped presses can also virtually eliminate job changeover issues – auto plate loading, along with print profiles that prepare the press for the next job, mean make-ready takes just a few minutes at most.

In closing, we would add one final note of caution: there was a UK printer that visited the last Drupa show convinced that he would order one of the clutch of B2 digital presses that were being launched at the event. He travelled back to the UK having done his sums, and ordered an RMGT 9 Series litho press.

What Next?

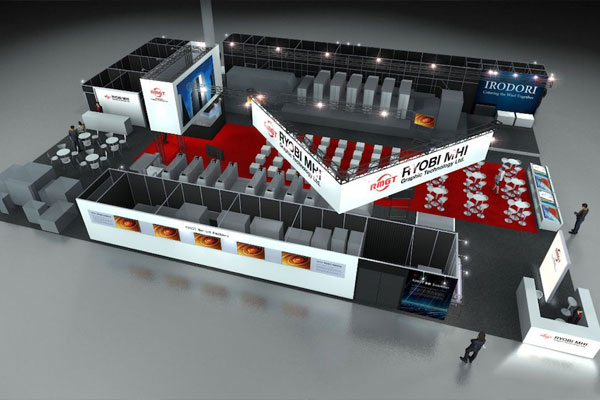

Ok, that’s our thoughts complete for now. UK and Ireland printers can contact MPL / M Partners for further advice and information. We will be on the RMGT stand in hall 16, stand E11, throughout the show. Please do drop by to say hello, we’d be delighted to meet with you and talk through any thoughts or questions that you may have, whether they are about digital or litho presses, or just the need for a sane chat about print or the show itself.

Future Releases Regarding Digital Production

Further research papers that we are preparing right now include facts and figures regarding power consumption – another important calculation that needs to be made; as well as one covering the true costs regarding those important environmental issues. There could be some surprising results in both areas. We look forward to releasing details in the near future.

For further information on RMGT offset printing presses, GUK folding and inserting products, Mabeg inspection systems, or about MPL please contact:

Russell J Hicks

Genesis Marketing Services (Milton Keynes)

21 Foundry Walk, Thrapston, Northamptonshire NN14 4LS

Phone: 07885 852 428

e-mail: Russ.Hxs@Gmail.com

© 2018 - 2023 M Partners Limited. All Rights Reserved | Site developed by JS Web Services | Design by D.Porter